Facility Auditing

Environmental Standards, Inc.’s facility audits… *add overview*

Environmental, Health and Safety (EHS) Audits are an important business tool for assessing liabilities and risks, satisfying requirements from regulators, and providing greater transparency to customers. For companies engaged in activities that fall under a regulatory agency, Environmental Standards auditors provide technical support and focused guidance based on over 30 years of industry experience.

Our team consists of experienced auditors who not only know the regulatory rules but have also implemented and assessed compliance against them. Our auditors help at the strategic level by maximizing competitive advantages from regulation and through the operational level by minimizing costs and disruptions to the business.

Why us

Your Advantage

Facility audits can set the stage for more effective negotiating when coupled to merger and acquisition deals. Our professionals have the capacity to rapidly identify asset-impacting EHS issues and prepare strategies to be used in sale price and deal-structure negotiations. We have represented hundreds of buyers and sellers in a broad spectrum of transactions ranging from simple, single site transactions to very complex multi-property, multi-national investment portfolios. Rapid analysis of potential EHS liabilities using in-house proprietary financial risk modeling tools can also assist our clients in better understanding the likelihood of certain business decisions resulting in certain outcomes and costs.

Our Teams

Our audit teams include certified auditors (e.g., CPEA, CPSA, CQA), professional engineers (PE), certified safety professionals (CSP), and certified hazardous material managers (CHMM). We work with our clients to design an EHS audit program, to reflect client philosophies, existing standards, or integrate programs with other audit functions. We also review existing audit programs against established audit program requirements to identify gaps or opportunities for improvement. Addressing the key elements for a successful audit program, Environmental Standards’ senior technical EHS professionals ensure that a comprehensive program is developed.

Our Process

Environmental Standards personnel have experience participating as team members and as leads for a number of audits. Our standard audit process includes: audit planning; hosting an opening meeting; participating on a facility tour; conducting activity review and on-site review; performing interviews with facility personnel; detailed records review; hosting daily debriefs and a closing meeting; final report generation; and corrective action verification.

National and International Service

Environmental Standards personnel have performed EHS audits nationally and internationally at the request of industry, law firms, and engineering firms. Our audits are performed against requirements established in agreement with clients and have included:

• industry codes of practice (e.g., Responsible Care)

• international standards (e.g., ISO 9000, ISO 14001, ISO 45001)

• environmental permits and plans (e.g., NPDES, Title V, Waste Water, SWPPP, SPCC, PPC, FRP, OPA)

• client specified standards

• contractual requirements

• method requirements (e.g., EPA 8260)

• regulatory requirements (e.g., OSHA, US EPA, USCG, DHS, DOT)

• legal requirements

• quality assurance project plan requirements

• audited entity requirements (e.g., standard operating procedures)

Environmental

Environmental compliance is an essential and unavoidable step of responsible EHS program management. Compliance, as a corporate or organizational goal, cannot be avoided or minimized. Additionally, maintaining environmental compliance is considered the minimum standard of care for responsible corporate or facility environmental management. Our Auditors reviewed compliance against a number of environmental programs including CAA, SDWA, CWA, EPCRA, SPCC, AST/UST, and RCRA

Audit Program Review

Many corporations have EHS audit programs have been chugging along for years, developing procedures and requirements to satisfy government regulations and when viewed as a whole, have been reasonably successful. Outliers do exist and a reasonable question is to ask why aren’t the EHS audit programs identifying the issues that cause these companies to be outliers. Success within an EHS Audit Program is often based on a combination of findings identification (e.g., total number of findings, number of high risk findings and number of repeat findings) and timely closure of corrective and preventative actions. A good question for any organization to explore is “Is your EHS Audit System having the impact you need?”

In this context, Environmental Standards examines a shift in audit program focus from identifying non-conformance and non-compliance as a measure of success to assessing and, if warranted, recommending options to strengthen the controls systems meant to manage specifically identified risks; such as, identification of the controls that are in place and specifically whether they are designed correctly, they are implemented fully and whether they are effective. In essence moving EHS audit from a checklist approach toward a risk based controls focus. Similarly, we will look at approaches to evaluate the EHS Audit Program from techniques to measure its success to utilization of a tiered audit approach and topic focused audits.

Health and Safety

Since the Occupational Safety & Health Act of 1970, employers have met with increasing challenges to provide their workers a safe work environment free of recognized hazards. Keeping up with the storm of constantly changing regulations can often be burdensome; the penalties for noncompliance are steep and no one wants to see people go home from work in worse condition than they started.

One of the more efficient methods for testing the integrity of your health and safety programs is through a third-party audit. From the office to the field, Environmental Standards’ safety auditors will conduct a thorough inspection of your site, focusing on safety hazards that present a real or potential hazard. Questionable behavior can be addressed “on the spot” and a full report, including photos and corrective actions, is typically delivered within 24 hours.

Process Safety Management and Risk Management Plan Audits

Environmental Standards conducts process safety management (PSM) and risk management plan (RMP) audits in accord with OSHA and US EPA regulations using highly experienced auditors/practitioners, many of whom are subject matter experts. Combining the disciplines of our auditors – engineering, chemistry, and safety – with the experiences gained by years of company and/or facility management, yields highly effective and value adding audits for our clients.

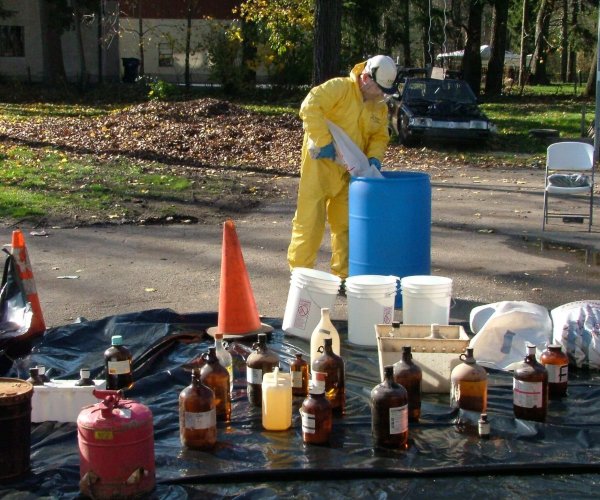

Waste Vendor Audits

As established under the Resource Conversation and Recovery Act (RCRA), a company’s liability for hazardous waste does not end when the waste is hauled away by a waste vendor (i.e., construction and removal contractors, waste haulers/transporters, waste transfer facilities, and facilities engaged in the Treatment Storage or Disposal of waste). Auditing waste vendors as part of a Waste Vendor Management Program is an effective way to manage and reduce that liability and risk.

In conjunction with procurement efforts, waste vendor auditing serves as an important mechanism to gather information to ensure consistency in waste vendor selection, criteria, and performance. Audits may be performed remotely (i.e., desktop audits) or on-site. Our audit team has performed numerous waste vendor audits across the US, auditing a wide range of waste vendors and their operations.

Transportation and Logistics Audits

Environmental Standards’ provides program- and procedure-level auditing and quality assurance support for a variety of transportation and logistics activities – whether transporting petroleum products or hazardous materials by truck, rail, pipeline, or vessel.