Critical Thinking in Data Validation: How Identifying Small Errors Can Have Big Impacts

Prospective Client:

“Why would I need to validate my data? My lab is accredited, and no one has had issues with the data.”

Environmental Standards Consultant:

“Data is so much more than just the lab report. Let me share some of what we’ve found over the years …”

This conversation prompted the idea for my presentation at the 2025 U.S. Department of Defense/U.S. Department of Energy (DoD/DOE) Environmental Data Quality Conference.

Data validation is a crucial step in assessing dataset quality. Yet too often, it’s narrowly viewed as a box-checking exercise focused only on reviewing laboratory results. In reality, validation should encompass all data associated with the project — from field collection to transport, laboratory analysis, and reporting. Although it may be known by different names (peer review, supervisory review, quality assurance/quality control [QA/QC]), the goal remains the same: ensuring the information you rely on is accurate and defensible.

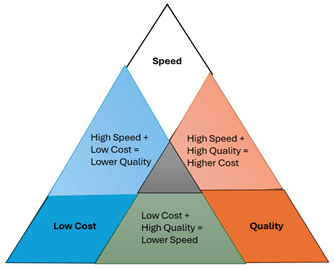

As with any project, the “iron triangle” of cost, speed, and quality applies. You can only choose two. While skipping data validation may seem like a way to save time or money, low-quality data almost always costs more in the long run. And when you’re making million- or billion-dollar decisions, the stakes are simply too high to rely on unchecked assumptions.

The Challenge of Automation

Automation has streamlined data workflows, making them faster and often cheaper. However, automation also introduces a trade-off: less professional judgment in the process. Data validation is rarely black and white. Subtle errors, variability across laboratories, and method modifications all require a human validator’s careful review. Documents and guidelines are helpful — but they can’t anticipate or cover every scenario.

Validation Starts Early

The best validation doesn’t begin after the laboratory report is delivered. It starts during project planning:

- Are the right sampling locations selected?

- Is field QC appropriate?

- Are custody seals, Chain-of-Custody (COC) Records, and field electronic data deliverables (EDDs) complete?

- Is the documentation detailed enough to recreate the sampling event?

Our philosophy is simple: If it isn’t documented, it didn’t happen.

Laboratory Checks

Once samples arrive at the laboratory, validation continues. Are you getting the right analytes for your project? Did the laboratory use the correct method — and do you know if any modifications were made? Something as basic as a “TCL Volatiles” request can result in 50 to 150 analytes, with lists that vary by laboratory and location.

Beyond the Checklist

When most people think of validation, they think of reviewing laboratory data. That’s where published guidance documents exist, but applying them requires discernment and judgment. Critical thinking entails going a step further:

- Recognizing when quality control results seem “off”

- Comparing against historical trends

- Tracking potential sample switches or contamination sources through field QC

- Catching calculation errors — such as incorrect methanol corrections, missed preparation factor adjustments, or calibrations with intercepts above the method detection limit (MDL) – which means a zero response would still be counted as a detection!

These aren’t one-off occurrences. We’ve encountered them repeatedly across projects, and they can significantly impact decision-making and lead to real-world consequences.

The Value of Human Judgment

While automation can flag issues, it cannot replace professional expertise. Identifying small errors often requires context, experience, and critical thinking. And those small errors, when overlooked, can cascade into big consequences, affecting site decisions, risk assessments, and ultimately, the cost of cleanup.

Validating your data isn’t an optional step — it’s the safeguard that prevents million-dollar decisions from being made on shaky ground.

If you are interested in hearing more, including stories illustrating these scenarios, I will be presenting a virtual Lunch and Learn event for the Greater Philadelphia chapter of the Society of Women Environmental Professionals (SWEP) on September 30th. More details and registration information can be found here.

Want to ensure that you have high-quality data to inform your decision-making? We can help! Our offerings include full-service QA oversight, Quality Assurance Project Plan (QAPP) preparation, laboratory program management, data validation, and more. Contact us today!